Metal fabrication is a viable solution for many businesses in need of custom metal work — whether that be for machine parts, product components, or custom metal products. P&D Metal Works in Neenah, WI provides businesses with custom metal fabrication in a variety of uses and companies interested in custom metal fabrication products may want to know more about processes like metal stamping. Learn more about the key differences between metal fabrication and metal stamping with this quick overview created by P&D Metal Works.

Metal Fabrication vs. Metal Stamping

To better understand the key differences between metal fabrication and metal stamping processes, it is important to define each concept.

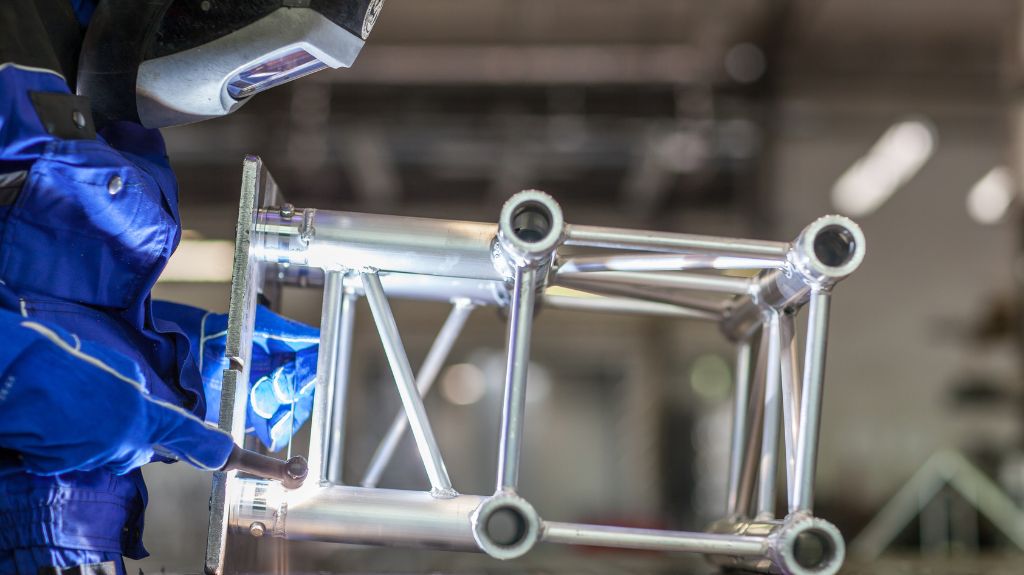

- Metal Fabrication — To put it simply, metal fabrication is the process of creating products and structures by cutting, bending, or welding raw metal materials. Metal fabrication is a broad term that includes many different processes in many different industries.

- Metal Stamping — Metal stamping is a specific process that employs customized dies and a metal press to form sheet metal into specific and identical shapes with higher volumes of production.

Here is a closer look at how these processes are different from each other:

Metal Fabrication vs. Metal Stamping: Processes and Operations

The key difference between metal fabrication and metal stamping is the process or processes that are used. Metal fabrication will use multiple processes to create the end product — including cutting, bending, welding, and assembling. With this in mind, metal fabrication is a more flexible process that can be used for many different projects. Metal stamping uses limited processes that are most often limited to pressing, punching, blanking, and bending.

Metal Fabrication vs. Metal Stamping: Production Volume

Metal stamping is a process that is built for high-volume production. It is an efficient and repeatable process that is perfect for multiple industries. Metal fabrication employs multiple processes and is most often used for custom one-time projects or low-volume production.

Metal Fabrication vs. Metal Stamping: Costs

The costs for metal fabrication and metal stamping will vary based on the specific project and the volume needed. When you choose metal stamping, there is a higher upfront cost to create the dies that are needed for the stamping process. This significant upfront cost is a reason why stamping is used for high-volume production to cut down on setup costs. Metal fabrication typically uses more standard operations, but may involve setup costs for multiple machines, which can add up.

READ MORE: Benefits of Laser Cutting for Custom Metal Fabrication

Do you have a metal fabrication project you need completed? Do you want to know more about the key differences between custom metal fabrication and metal stamping? We hope this breakdown created by P&D Metal Works has answered your questions.

Contact P&D Metal Works today to kickstart your metal fabrication project!